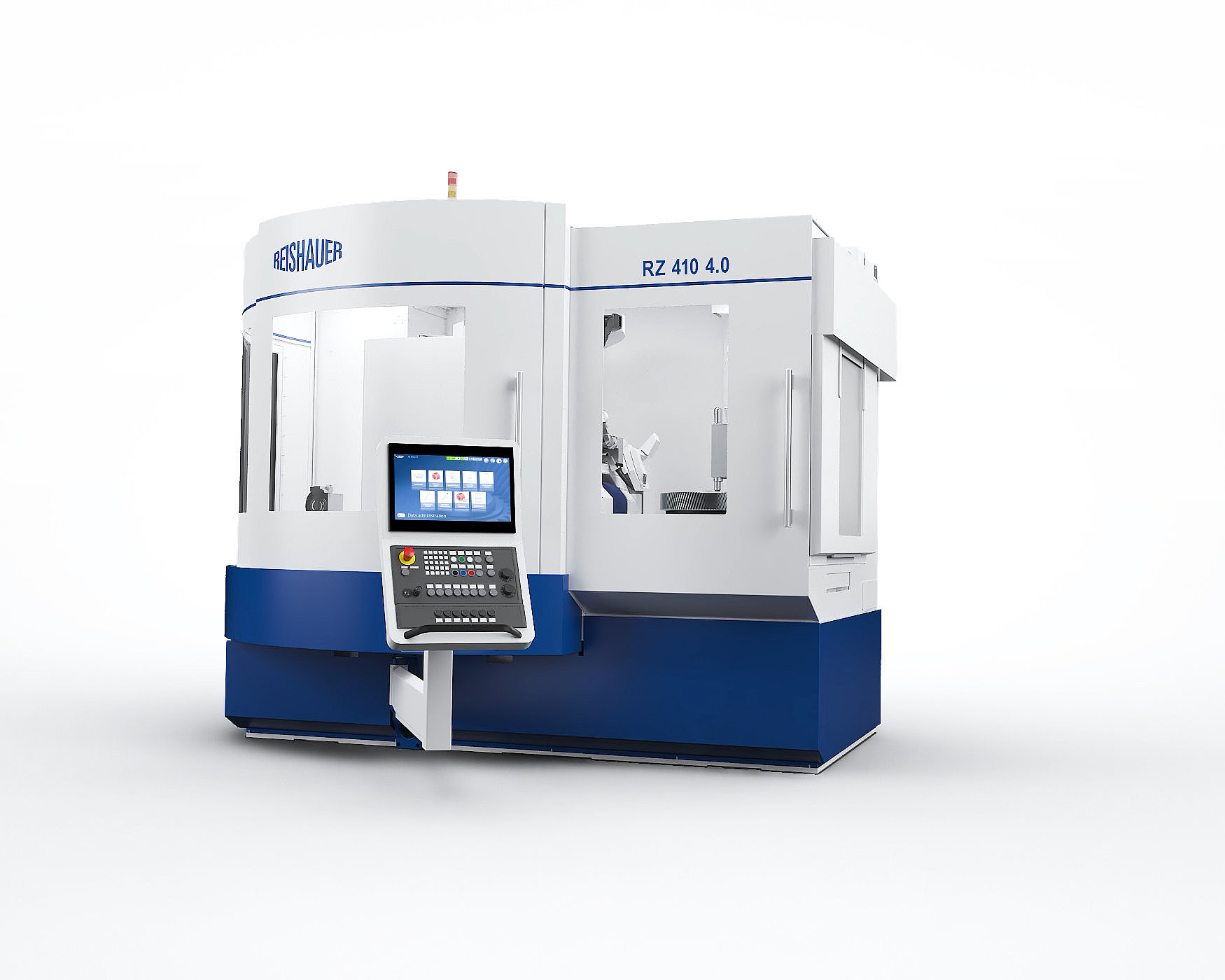

Continuous Generating Gear Grinding Machine RZ 410 4.0

The Job Shop Machine

The RZ 410 4.0 gear grinding machine combines universality, high precision and robust material removal rates. This machine represents state-of-the-art gear grinding technologies. As the grinding oil flow is completely separated from the machine bed, it features extraordinary thermal stability.

Flexibility and Productivity

The grinding diameter range of 5 to 410 mm and its module range of 0.5 to 10 mm covers a wide range of gear grinding applications. Technologically speaking, the RZ 410 is identical to the larger grinding machines, the RZ 550 and RZ 1000, which, in the main, differentiate themselves in their grinding diameter ranges. Short set-up times and excellent accessibility underscore the flexibility of this family of grinding machines.

Profile grinding (tooth gap by tooth gap), line dressing and the on-board gear measuring option exemplify the wide field of application of these machines.

The swivable dressing unit allows the application of all of Reishauer’s dressing technologies such as, among others, line dressing, dressing with multi-rib full profile rolls and topological dressing.

The worldwide market acceptance of this machine speaks for itself.

Working Range

Hardware Options (Extract)

Technology Options (Extract)

Control

- Low Noise Shifting reduces the noise generation in transmissions

- Polish grinding improves the performance of transmissions

- Twist Control Grinding allows deliberate modification of contact patterns of gear teeth

- Generating gear grinding of asymmetrical designs

- Line dressing offers highest flexibility for grinding prototype gears

- Grinding of beveloid gears widens the machines field of application

- Profile grinding for grinding gear set-ups with interfering contours

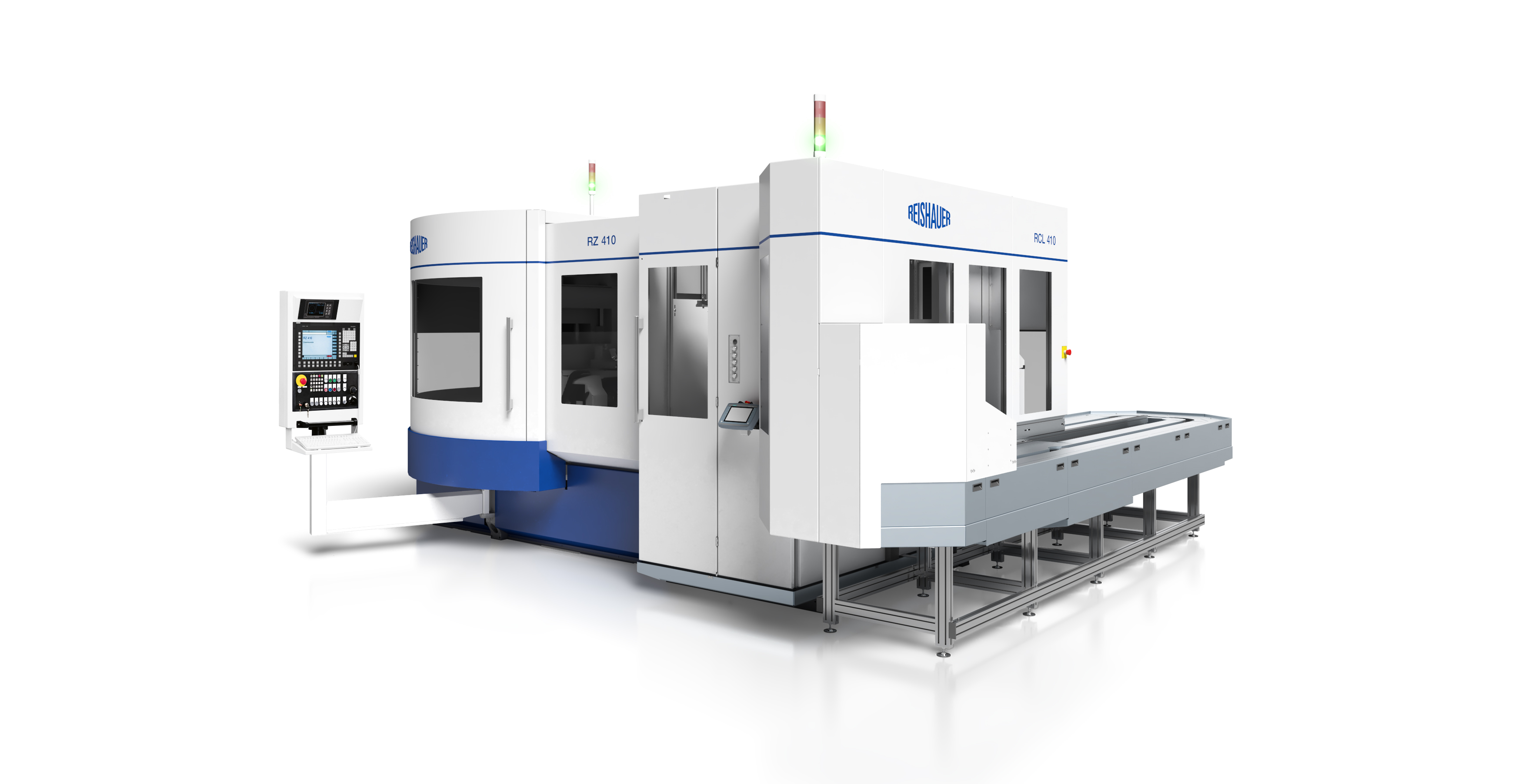

Loader System Reishauer RCL 410

The Reishauer RCL 410 offers a variant for the Reishauer universal grinding machines of type RZ 410. In principle, the loader is also suitable for the larger RZ 550 and RZ 1000 machines.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/5/csm_06239_2cec8cc240.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/d/a/csm_08091_fc08fcc13d.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/7/2/csm_08094_8283c690ca.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/2/csm_09164_b2a3bbd6a0.jpg)