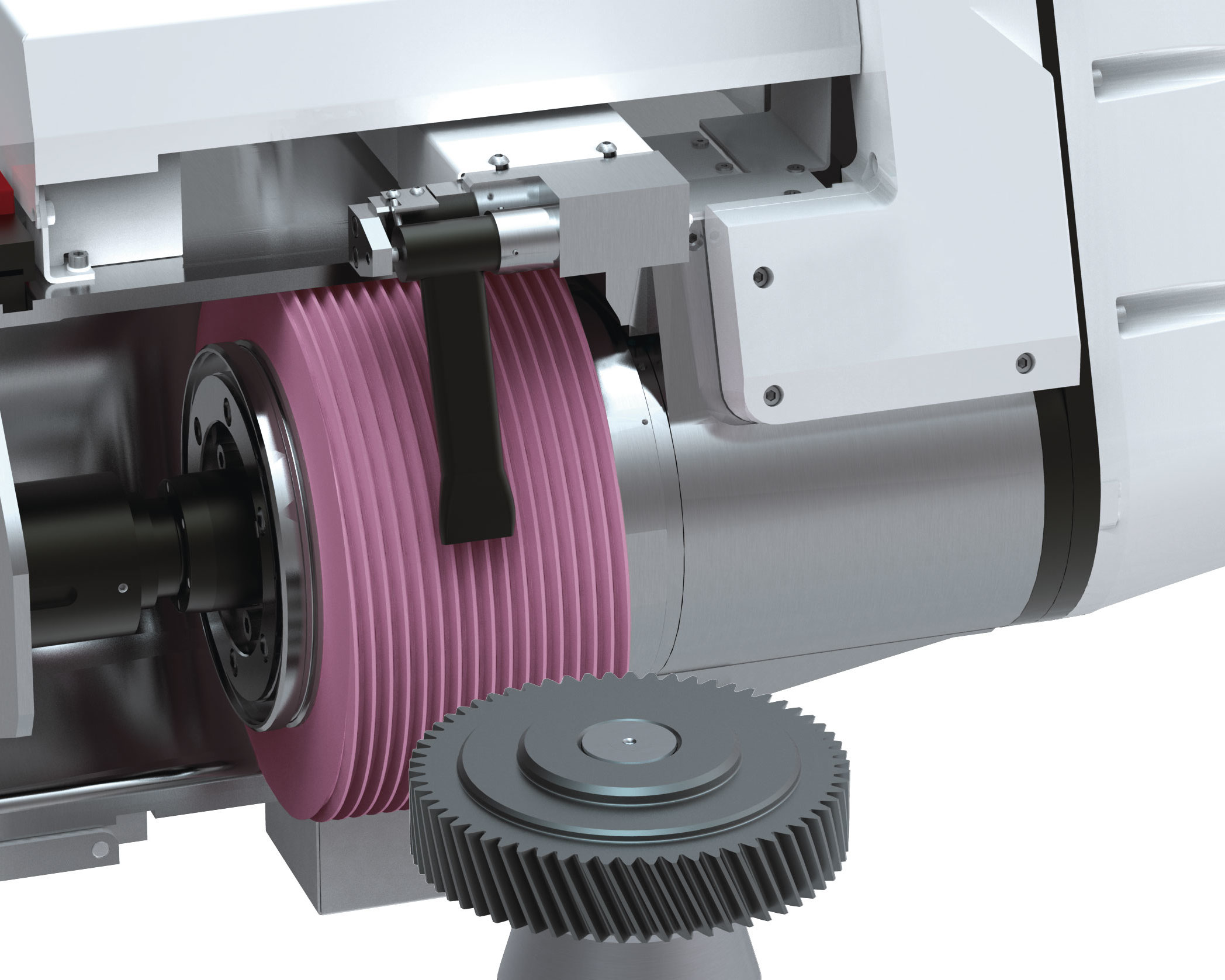

Continuous Generating Gear Grinding Machine RZ 260 4.0

From automotive ring-gears to gears for medium-sized trucks

The RZ 260 4.0 gear grinding machine covers the largest range of workpieces for the automotive industry. This includes all gears for car transmissions and gears of medium-sized trucks, ranging in diameter from 0 to 260 mm, and from module 0.5 to 5 mm.

Constant High Performance

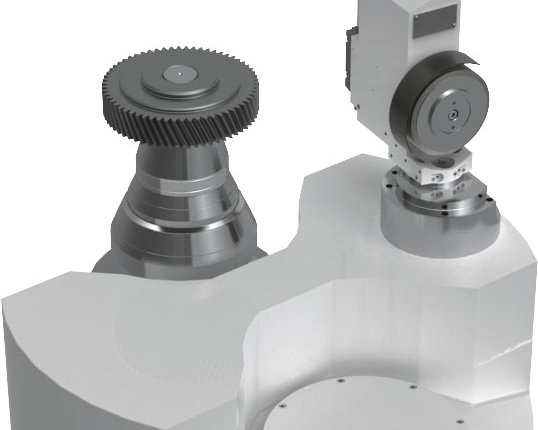

The RZ 260’s overriding design principle is based on its dual spindle technology, with all axes movements and routines being uncompromisingly executed in parallel, the short reaction times of all spindles, and the high cutting speeds.

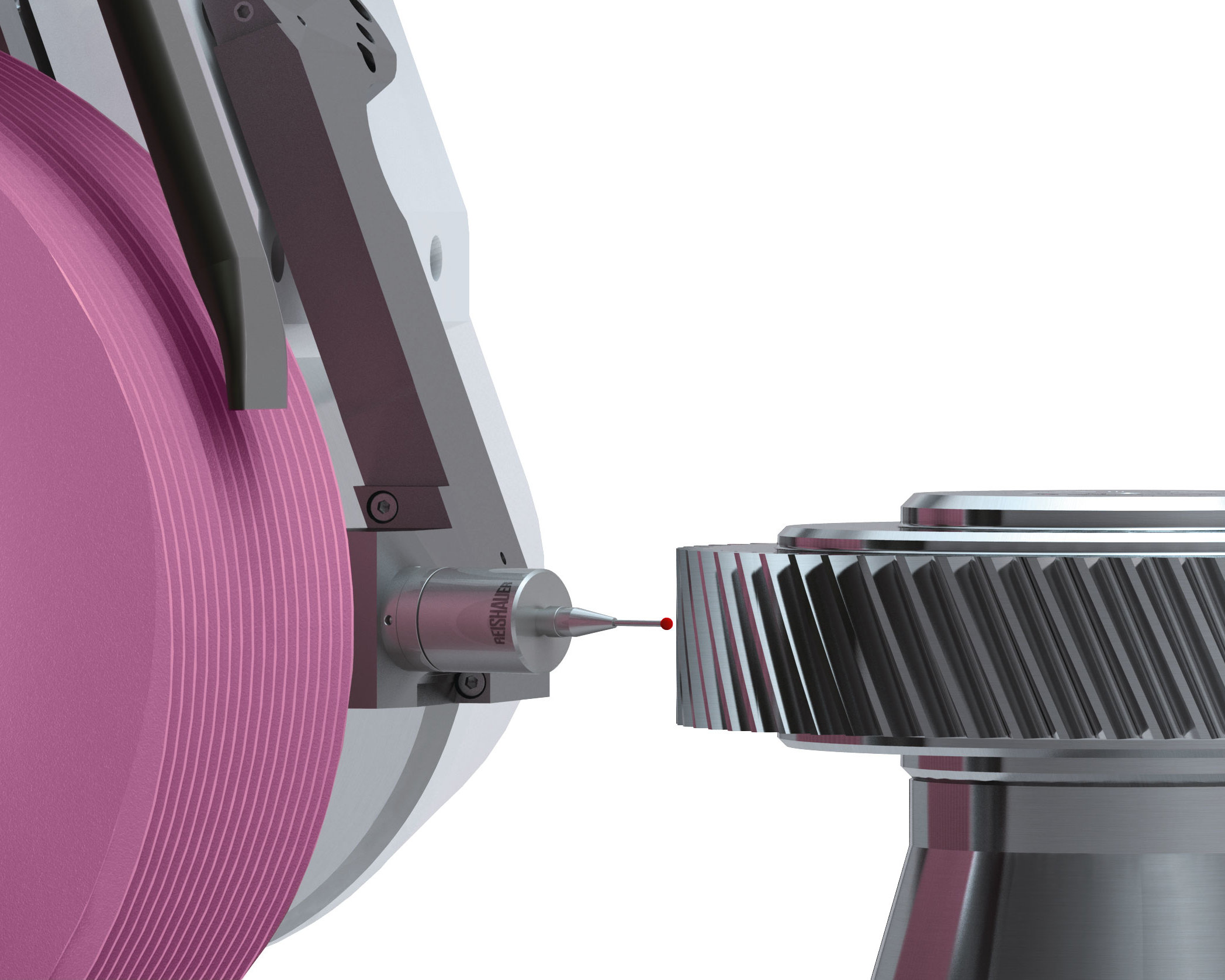

The swivable C-dressing axis allows applying all of Reishauer’s dressing technologies such as line dressing, dressing with multi-rip full profile rolls and topological dressing.

Short set-up times highlight the flexibility of the machine. Apart from disk-type workpieces, this machine equally handles shaft-type workpieces with its optional tailstock. The operating philosophy is identical to that of the other two types machines of the RZx60 family. As a result, operators that are familiar with the RZ 60 4.0 and RZ 160 4.0 can immediately, and productively, operate the RZ 260 4.0 machine.

Due to its compact design, and the fact that it comes fully equipped, it can be easily integrated into existing production lines.

Last but not least: hundreds of RZ 260 machines that unflaggingly generate income for our customers are the best proof of the performance level of this machine.

Working Range

Hardware Options (Extract)

Technology Options (Extract)

Control

- Low Noise Shifting reduces the noise generation in transmissions

- Polish grinding improves the performance of transmissions

- Twist Control Grinding allows deliberate modification of contact patterns of gear teeth

- Generating gear grinding of asymmetrical designs

- High speed grinding at 100 m/s reduces grinding times and the risk of grinding burns

- Line dressing offers highest flexibility for grinding prototype gears

- Grinding of beveloid gears widens the machines field of application

- Profile grinding for grinding gear set-ups with interfering contours

Part Loader System Reishauer RL x60

Reishauer’s own automation concept is an integral part of its performance portfolio. This part loading automation keeps pace with the machines fast cycle times, productivity and availability. Automation and machine are in perfect synch as they share their place of...

Loader System Reishauer RCL x60

Loader systems offer the customer functions that supplement the production process before and after the grinding operation. Integrated monitoring and ejection functions ensure a consistently high quality of output. These features help our customers to organize production...