Profile Grinding

of collision-critical workpieces

The profile grinding heads PSK extend the application possibilities of the Reishauer generating grinding machines. They enable the grinding of gears with very small modules and diameters that feature interfering contours.

Profile grinding is an efficient method for the production of prototypes and small lots. Gear profile modifications can be achieved by simply reprogramming the dressing path by using the existing profile grinding dressing tools.

Conversion to the profile grinding head is completed in as little as 20 minutes. On the software side, most Reishauer machines are already prepared for profile grinding. On the hardware side, a B-grinding spindle with «Performance» design is a prerequisite. Two variants of the profile grinding head are available:

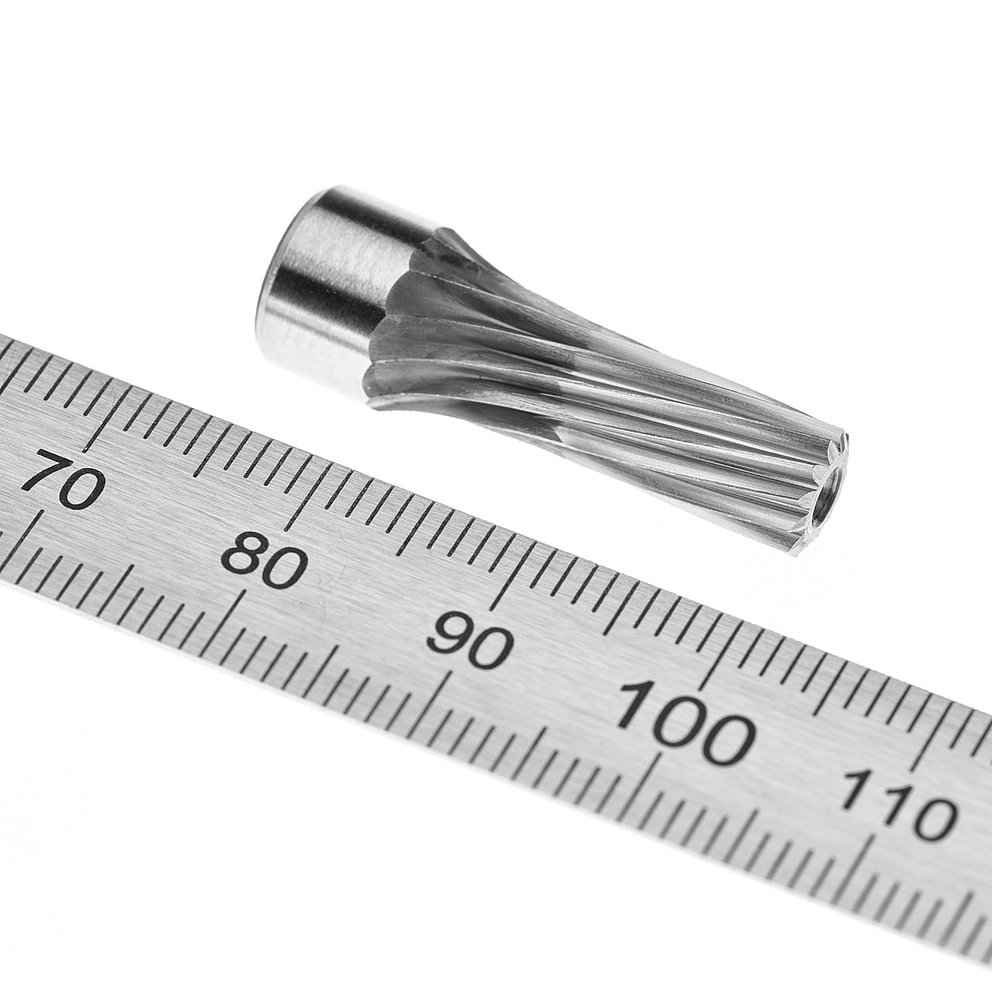

PSK D10 profile grinding head (RZ 160 4.0 and RZ 260 4.0 only)

10 mm shaft diameter for approaching particularly restricted machining areas

- Diameter of grinding tool: da max: 50 mm; df min: 20.5 mm

- Maximum grinding wheel rotational speed: 27 500 min−1

- Module range: 0.5 – 2.5 mm

Profile grinding head PSK D20

20 mm shaft diameter for a wider module range

- Grinding tool diameter: da max: 160 mm; df min: 42.0 mm

- Maximum grinding wheel rotational speed: 14 500 min −1

- Module range: 0.5 – 4.0 mm