Generating Grinding Machine RZ 126/160 KWS 4.0

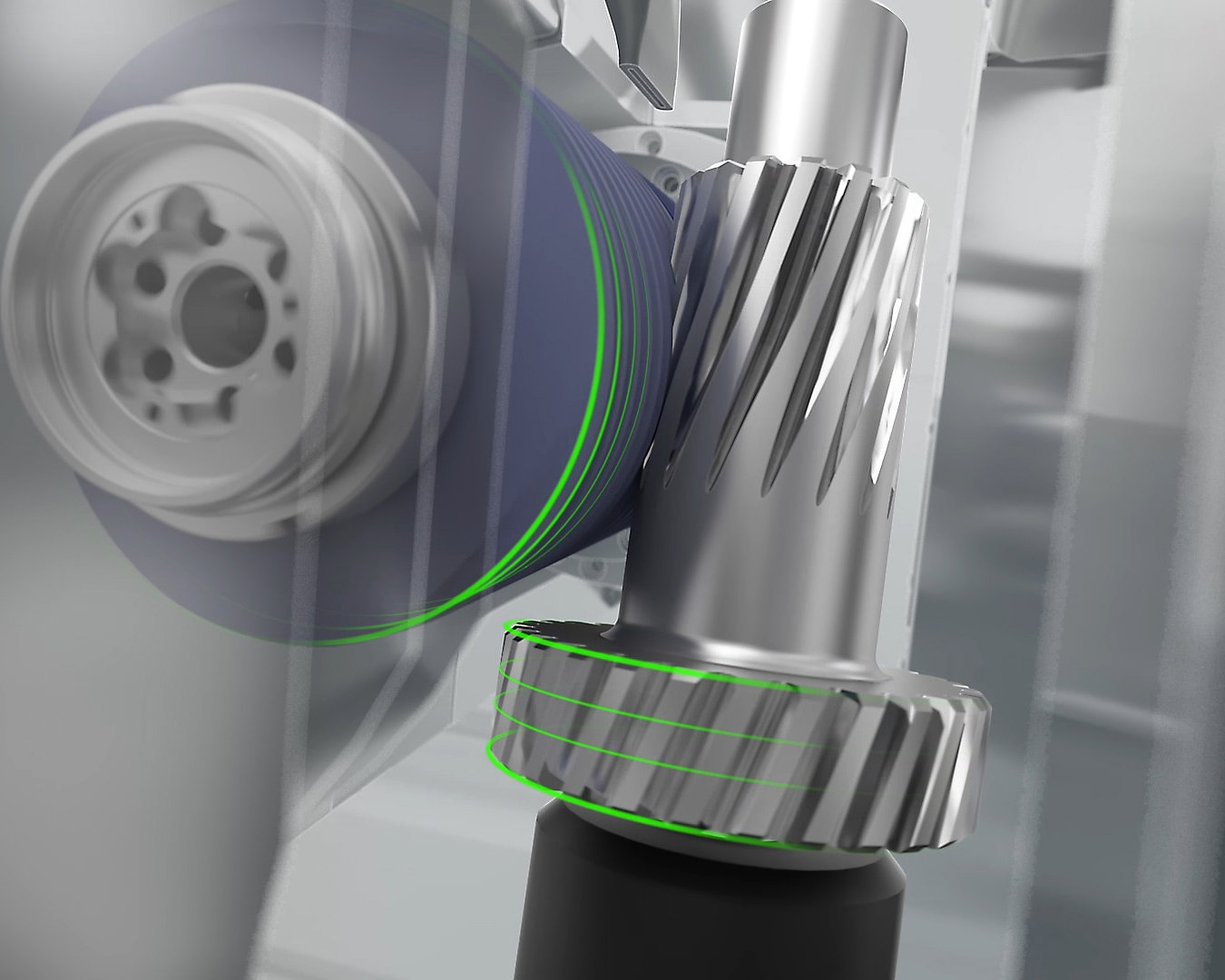

Grinding parts with interfering contours

The Reishauer KWS series, featuring small diameter grinding worms, has enabled us to keep pace with the rapidly expanding electric mobility market. In this way, we have created further opportunities for our customers who require efficient high-volume production of high-precision gearing with collision-critical workpieces.

Ensures the productivity advantages of continuous generating grinding

If you look at processing times, generating gear grinding is superior to discontinuous grinding processes in practically all respects. In particular, the design of the grinding machine with two workpiece spindles enables loading to take place without affecting primary machining time. This can significantly shorten grinding cycles and thus achieve low unit costs.

To keep providing you with the productivity of generating grinding with Reishauer level quality and precision, we have further developed two variants from our proven Reishauer 4.0 model series. Both the RZ 126 KWS 4.0 and the RZ 160 KWS 4.0, the latter designed for larger workpieces, enable efficient generating grinding of gears with interfering contours.

Working Range

Standard Features

Options (extract)

Control

- Low Noise Shifting reduces the noise generation in transmissions

- Polish grinding improves the performance of transmissions

- Twist Control Grinding allows deliberate modification of contact patterns of gear teeth

Part Loader System Reishauer RL x60

Reishauer’s own automation concept is an integral part of its performance portfolio. This part loading automation keeps pace with the machines fast cycle times, productivity and availability. Automation and machine are in perfect synch as they share their place of...

Loader System Reishauer RCL x60

Loader systems offer the customer functions that supplement the production process before and after the grinding operation. Integrated monitoring and ejection functions ensure a consistently high quality of output. These features help our customers to organize production...