ARGUS Monitoring System

Making Generating Gear Grinding Transparent

Reishauer’s ARGUS process and component monitoring system gives you new insights into grinding and dressing processes and the running state of your critical machine components. Insights that were previously simply not possible. The system enables you to monitor and optimize processes, to early detect and predict maintenance issues, to plan efficiently, and to reduce downtimes to a minimum. ARGUS makes all that possible!

ARGUS...

- is the monitoring system that helps prevent costly disassembly and unplanned downtime

- detects faulty dressing during the process

- is essential to optimize the workpiece-specific grinding process

- enables data-driven workpiece evaluation by using complex algorithms to remove faulty gears at an early stage

- is self-diagnostic, thus simplifying the coordination of service and maintenance planning

- is a database-supported tool that maps OEE as well as tracing other key data

- can be retrofitted on existing RZ x60 machines to a certain extent!

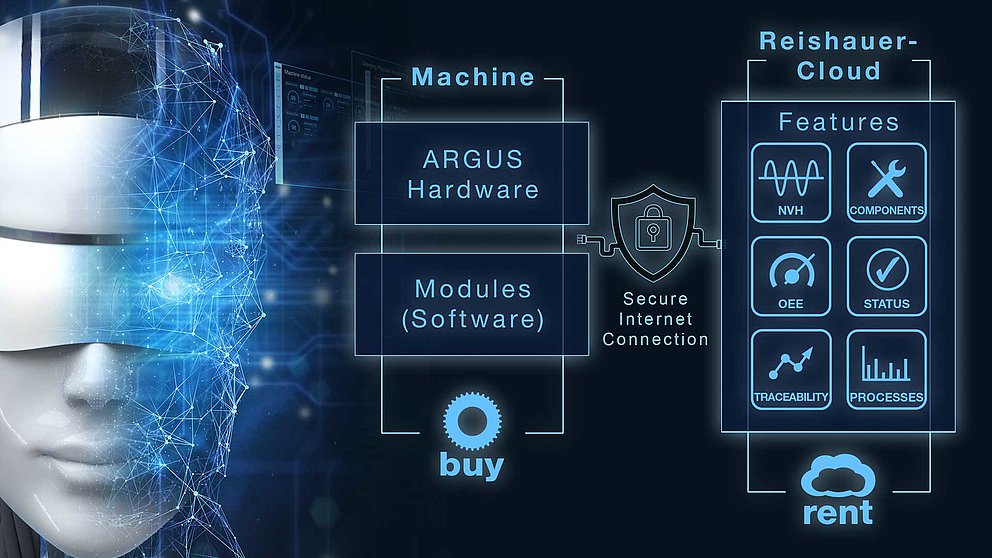

The ARGUS monitoring system consists of hardware components, machine-side software (modules), and digital products (features) available to users connected to the Reishauer Cloud. The functionalities of the modules focus on analyzing and evaluating all machining processes taking place on the grinding machine. Here, the aim is to enhance process stability and productivity through consistent dressing and grinding quality. The features available on the Cloud produce a precise picture of all grinding machines connected to it, including their complete history, in real-time. The highly innovative NVH-related feature brings the production of gears and transmissions closer together.