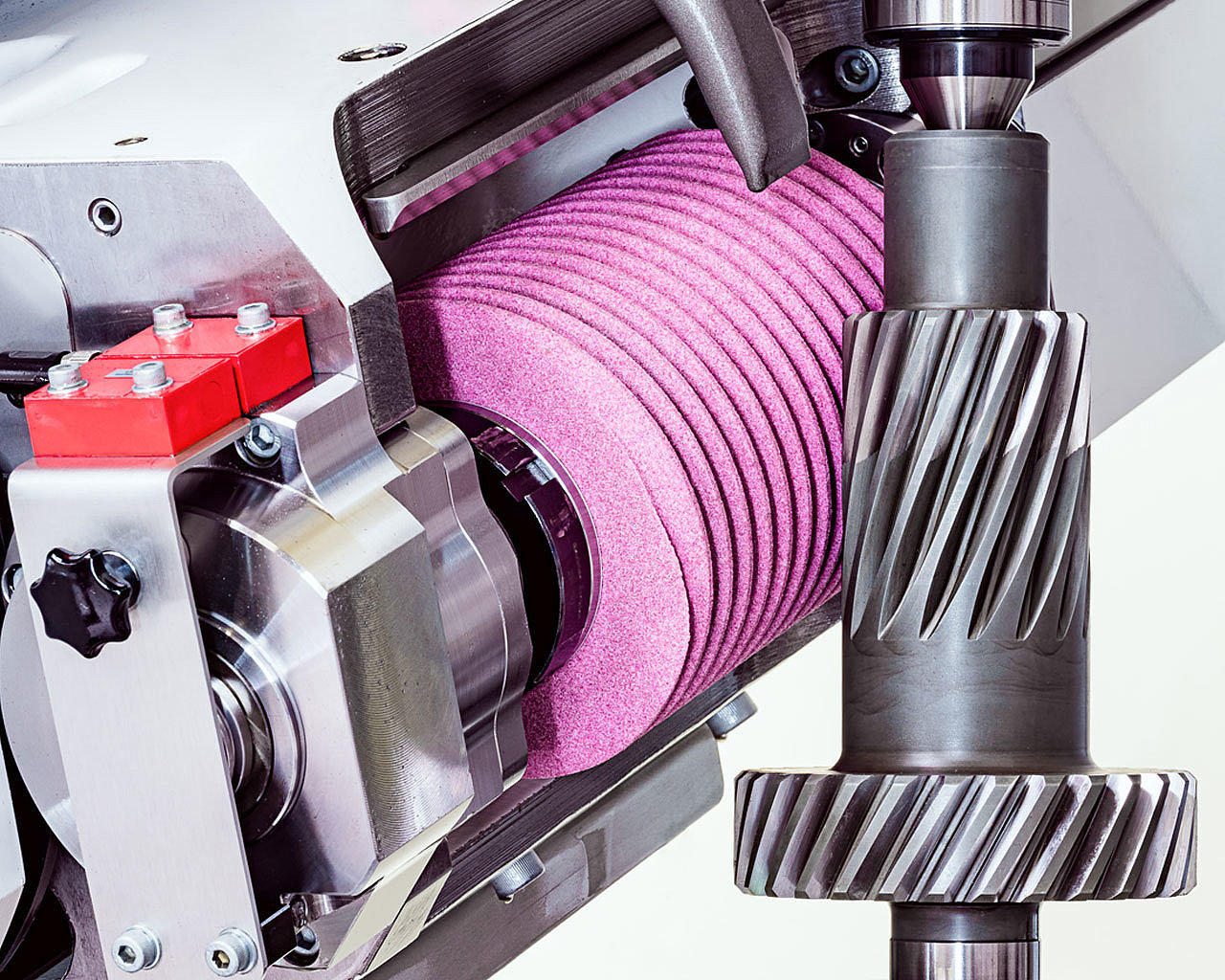

Small Spindle Attachment

Upgrade module for maximum flexibility

For companies that want to cover a wider range of gear designs with just a few machines, the Small Spindle Attachment expands the range of services and offers new possibilities.

Maximum flexibility on one machine

The upgrade module for the Reishauer RZ 410 to RZ 1000 uses a corundum grinding worm, reduced in diameter to 140 mm (df min 67 mm), making the advantages of the generating grinding process available for extended applications. It thus fills the gap between our highly productive RZ 126 / 160 KWS 4.0 twin-spindle models and the profile grinding process.

The Small Spindle Attachment...

- ... enables efficient generating grinding of gears with interfering contours

- ... expands the range of workpieces to be ground

- ... uses the same machine working range for diameter and number of teeth

- ... fulfills machining accuracy 5 according to ISO / DIN

- ... covers the module range 1 – 4 mm (other module ranges on request)

- ... requires less than 45 minutes changeover time

- ... is suitable for models RZ 410 to RZ 1000, also with optional loader

The Small Spindle Attachment can be retrofitted to the Reishauer RZ 410 / 550 / 1000 from year of manufacture 2014, starting with machine number 75 345 (RZ 410 / 550) or 75 931 (RZ 1000).

Working Range

Dimensions that may differ can be verified upon request.

Grindable modules

1.0 – 4.0 mm

Grinding spindle speed

max. 10 930 min⁻¹

Cutting speed

max. 80 m/s

Grinding wheel diameter da max

max. 140 mm

Grinding wheel root diameter df min

min. 67 mm

Dressing tool diameter

160 mm